The subsequent analysis of the 3D model is also fully automatic

CNC-controlled axes that can also be moved manually for sample measurements.

The software automatically detects the greatest wear on cutting edges

»Z3dCam« captures a wide variety of tool geometries and defined measurement ranges quickly and precisely.

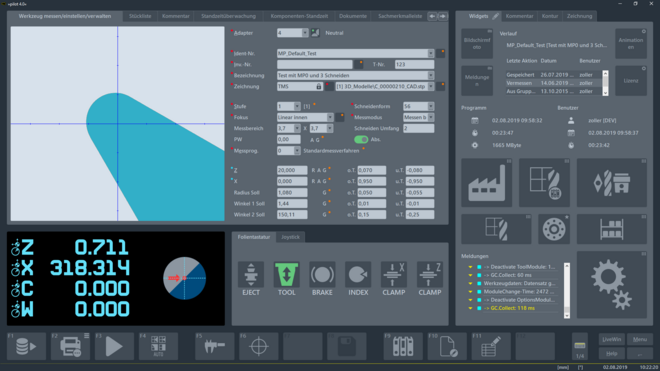

Modern design and even more features: The software for all-inclusive tool measurement

»pilot 4.0«| Max. tool length | Max. tool Ø (with / without swivel mechanism) | Max.snap gauge Ø | Number of axes | Weight | |

| »edgeControl« | 600 mm | – / 100 mm | 100 mm | 5 | 1.400 kg |

Would you like to supply your customers with 100% quality and / or sharpen them efficiently and therefore need to quickly and precisely identify breakouts or wear on tool cutting edges? The universal measuring machine »edgeControl« detects tool breakouts on all cutting edges quickly and fully automatically. The 3D sensor takes on this demanding task. The sensor is automatically aligned to the cutting edge and the cutting edges are digitized in 3D including simultaneous path control of the axes. The subsequent analysis of the 3D model is also fully automatic and can be influenced manually if required. The »pilot 4.0« software automatically detects the greatest wear on cutting edges, calculates it and exports the data to the grinding machine in a control-appropriate manner. Your tools are optimally ground and achieve longer life cycles. This increases quality and resource efficiency.