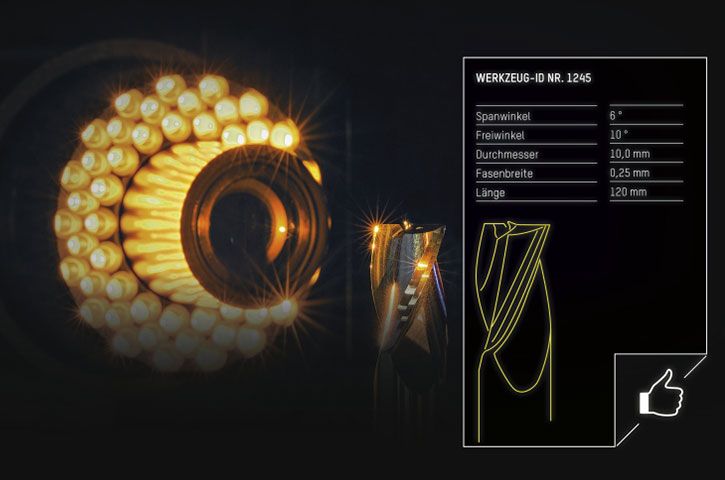

Touchless inspection of cutting tools in incident light

Automation solution for autonomous measuring

Data transfer as the basis for seamless processes

Play it safe: Documentation included

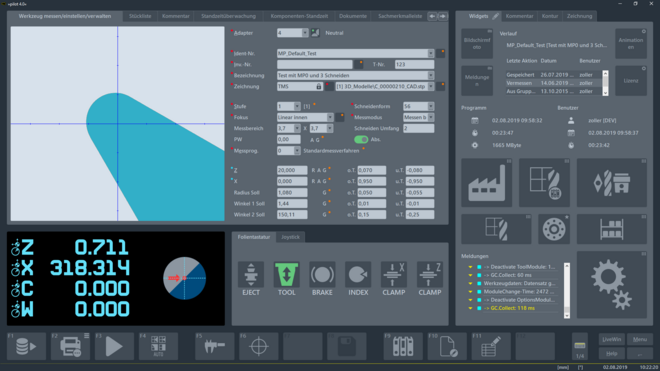

Modern design and even more features: The software for all-inclusive tool measurement

»pilot 4.0«| Measuring range Z | Measuring range X | Measuring range Y | Measurable tool Ø | Snap gage Ø | |

| »genius« | 600 mm (23.6 inch) | 175 mm (6.9 inch) | 100 mm (3.9 inch) | 400 mm (15.7 inch) | 100 mm (3.9 inch) |

Vertical and Horizontal Dimensions, Radius, and Angle of Standard Cutting Tools

Measuring program for the simple measurement of vertical and horizontal dimensions, radius and angle of standard cutting tools.

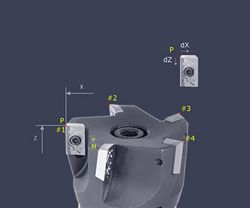

Conical Reamer - Snap Gauge Method

Measuring program for the measurement of single-edge reamers with support bar and with the snap gauge method.

Single Cutting Edge Reamer - External Processing

Measuring program for the measurement of any parameters at the outer edge of single cutting edge reamers.

Theoretical Tip

Measuring program for the determination of the theoretical tip at tapered cutting tools over several measuring points.

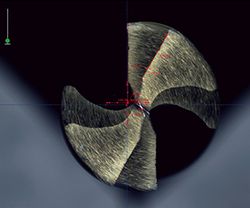

The ZOLLER-»genius« is the universal measuring machine for cutting tools. From the quick inspection of individual criteria to the fully automatic and user-independent complete check, your tools are checked quickly, simply and with maximum precision. Measuring results are documented in detail and can be transferred to your grinding machines with a simple click. This means that the »genius« saves you valuable time in work preparation and programming, eliminates unnecessary reworking and customer complaints, and ensures a quality which will impress both you and your customers.

“For me, assembling each and every »genius« is a personal project through which I renew ZOLLER's quality promise to our customers. As an assembly technician, I know every assembly group and every screw. Every component that makes a »genius« so amazingly precise and versatile passes through my hands. And I know from years of assembly experience why the construction of the »genius« is so unbelievably solid.

That’s why I can assure you: When you buy a »genius«, you will get a machine that will impress for its precision and long service life.” Witold Hutka, Measuring Machine Assembly Technician at ZOLLER